This is the first in a series of posts on the 2018 Steffens-Colmer Studios and Don Coltman Company Photographs Digitization Project, funded by the British Columbia History Digitization Program.

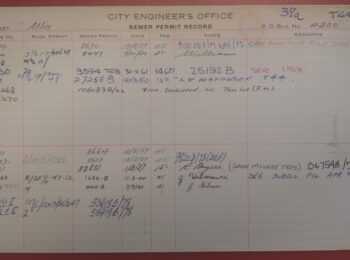

We are working on a project to digitize thousands of negatives created by commercial photographer Don Coltman. His photographs are all public domain copyright, cover a wide variety of subjects, and will be freely available for use once the project is finished. These negatives are made of rapidly deteriorating cellulose acetate, which is a health hazard. They are stored frozen to keep them from deteriorating further. We had to develop a way to digitize the negatives that would be

- safe for our staff (reduce their exposure to a hazard) and

- safe for the negatives (reduce their time out of freezer storage)

CELLULOSE ACETATE NEGATIVES

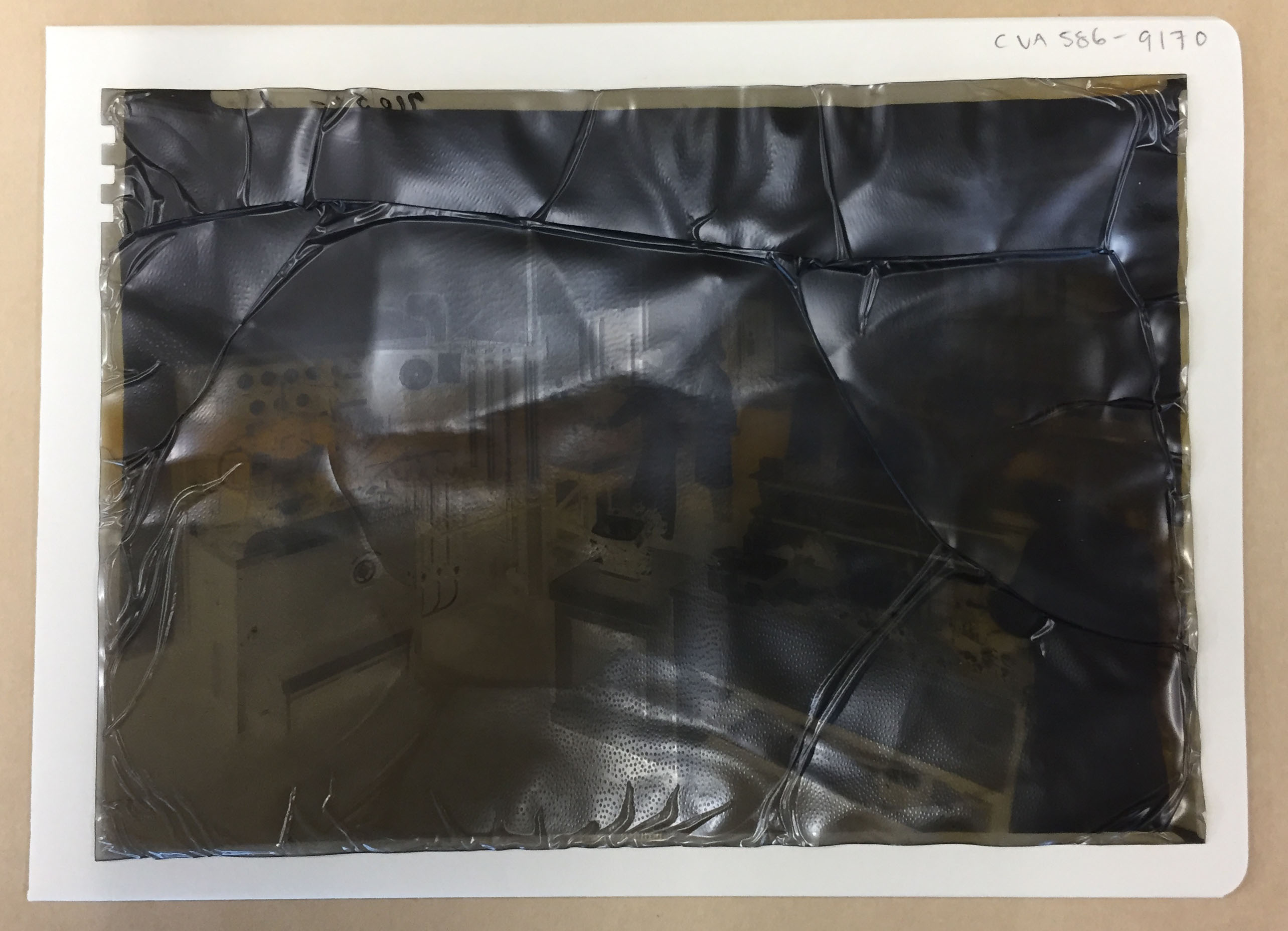

We’ve written about the problems of cellulose acetate negatives before. As they deteriorate, they give off acetic acid, which is harmful if inhaled or absorbed by skin, eyes or contact lenses. They also smell like vinegar. The Coltman negatives are some of our smelliest acetate negatives; they were one of the main reasons we hurried to build the Friends of the Vancouver Archives Photographic Cold Storage Facility. In the decades since they were frozen, their deterioration has been almost completely stopped, but as soon as they are thawed for digitization, they give off more acid.

We are pleased that there are only a few negatives in this project that are so badly deteriorated that they are very distorted. The rest of the negatives are as flat as when they were first frozen.

DIGITIZATION SETUP

We considered setting up the digitization equipment in an old photographic darkroom that had been fitted with vapour extraction many years ago. The darkroom has a lot of flat working space, so we would have had room to spread out the equipment. Unfortunately, when the City’s Occupational Safety Specialist tested the vapour extraction system, it was not strong enough to remove acid vapours.

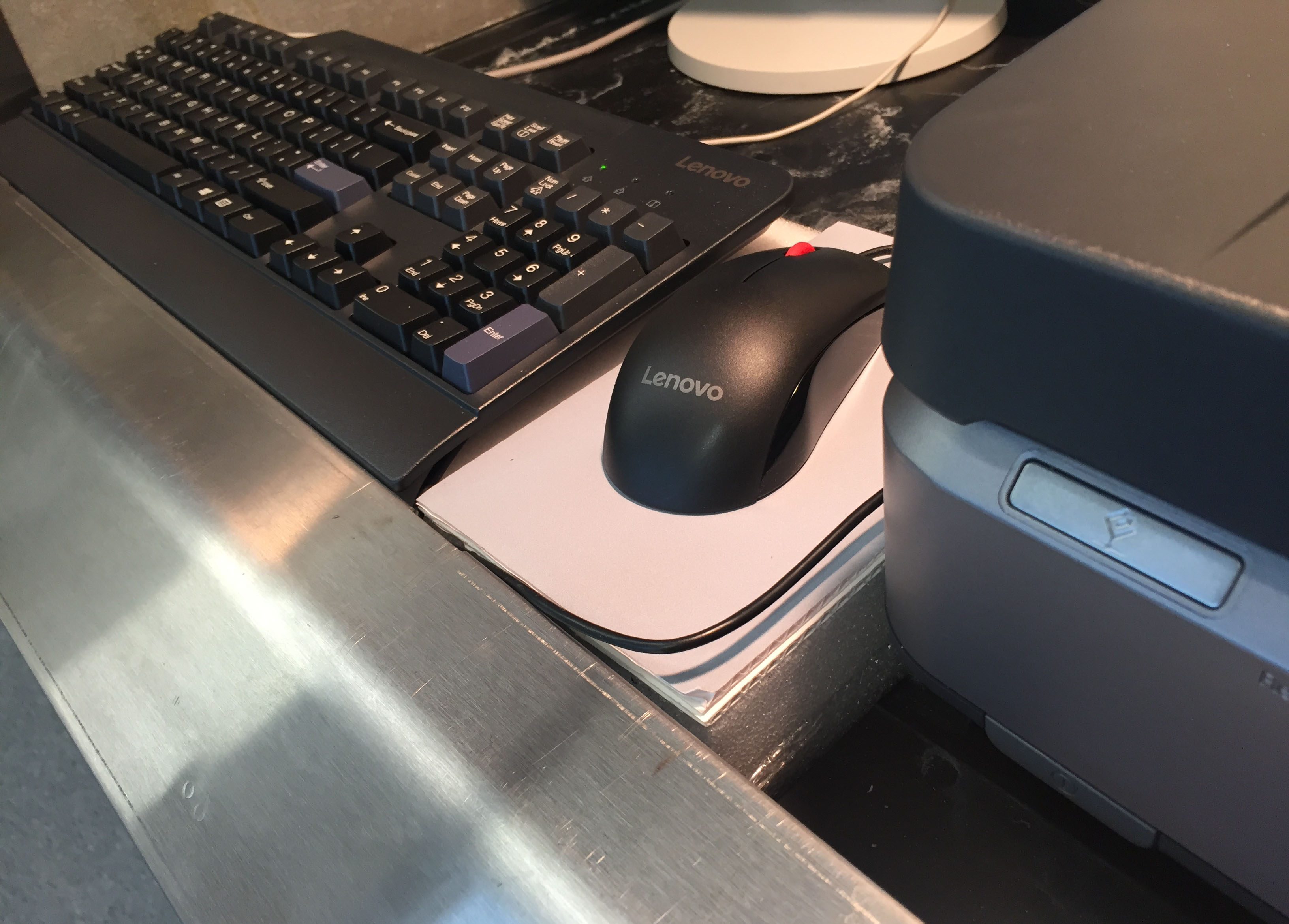

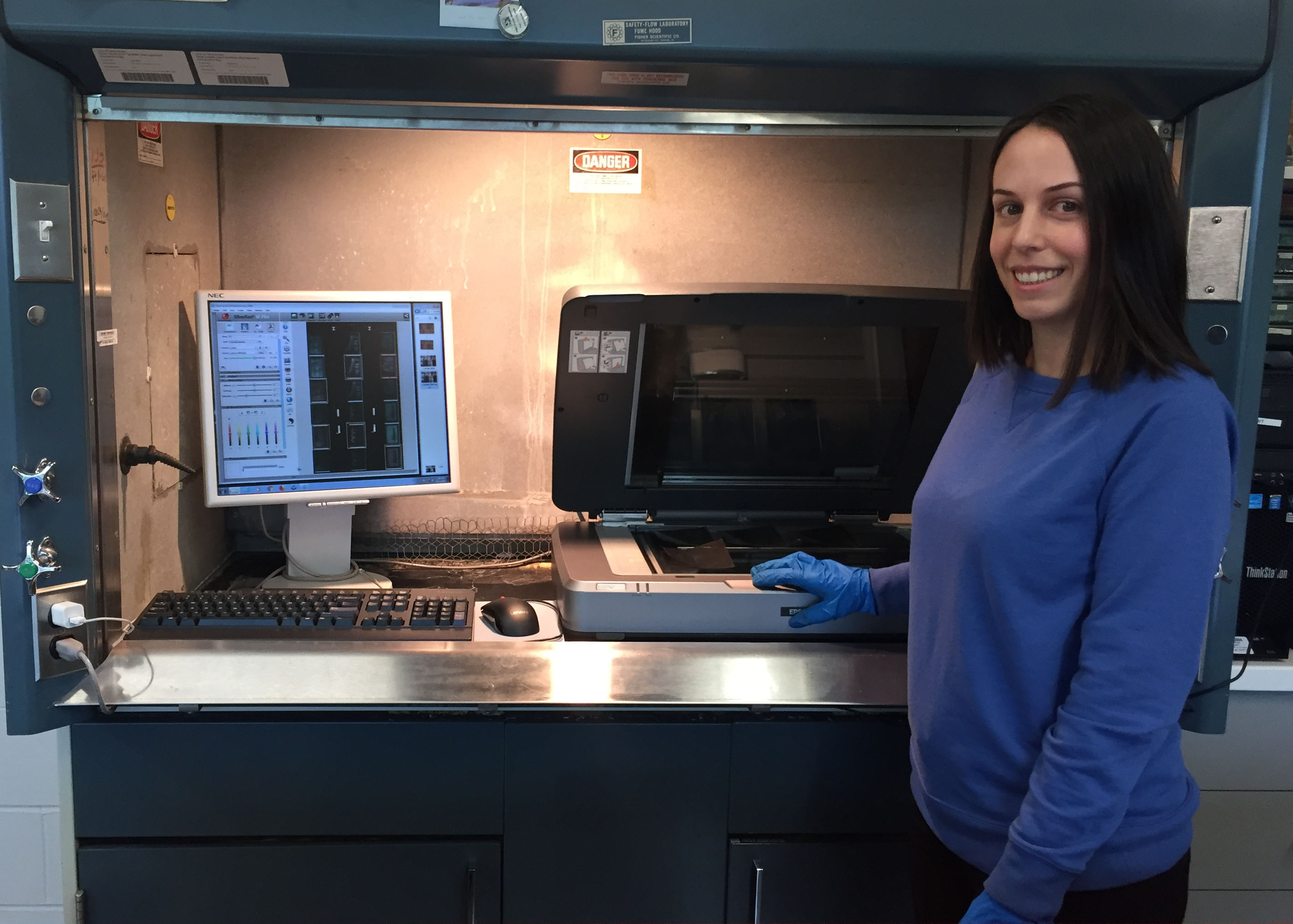

Next, we looked at the fume hood in our Conservation Lab. We knew the vapour extraction was excellent, but it was going to be a tight fit for our equipment. With the computer outside the fume hood, there was just enough room for the rest of the equipment inside.

Since the fume hood has a stainless steel sill that is 5cm above the level of the surface inside, we created a platform out of foam to raise the keyboard and mouse to a comfortable working height level with the top of the sill.

This setup has been working well since May.

WORKFLOW

In order to limit the amount of time the negatives spent thawed, we made many trips into the freezer every day to retrieve and return small batches of negatives. Once they were thawed, the negatives would be scanned onto an external hard drive. The scans would be processed and inspected at one of our digitization workstations elsewhere in the building, using a better monitor. Then the negatives could be returned to the freezer.

We will let you know when these images are available in our database. In the meantime, here are a couple more as a preview.

Thank you for your wonderful information, check_out one of the most reputed

Fume Extraction System Manufacturers Chennai, Fume Exhaust System Manufacturers Chennai

Fascinating process and great work! Thank you! Look forward to being able to look at more of these images once the project is done. And thank you for the information on the chemistry of cellulose acetate photography and the preservation process.